Accelerating the introduction of innovations to the market

Scaling processes, from laboratory conditions to industrial standards, is a central challenge of modern production technology. The transition from the laboratory bench to industrial production is filled with various challenges, as larger-scale effects that were not observed in the laboratory often come into play.

These unpredictable scaling effects must be understood and eliminated. It is necessary to comprehensively scale processes, evaluate novel processes, and test them in an industrial environment to make new technologies attractive and marketable for industrial application.

What are the implications of technology scaling for us at Fraunhofer FFB?

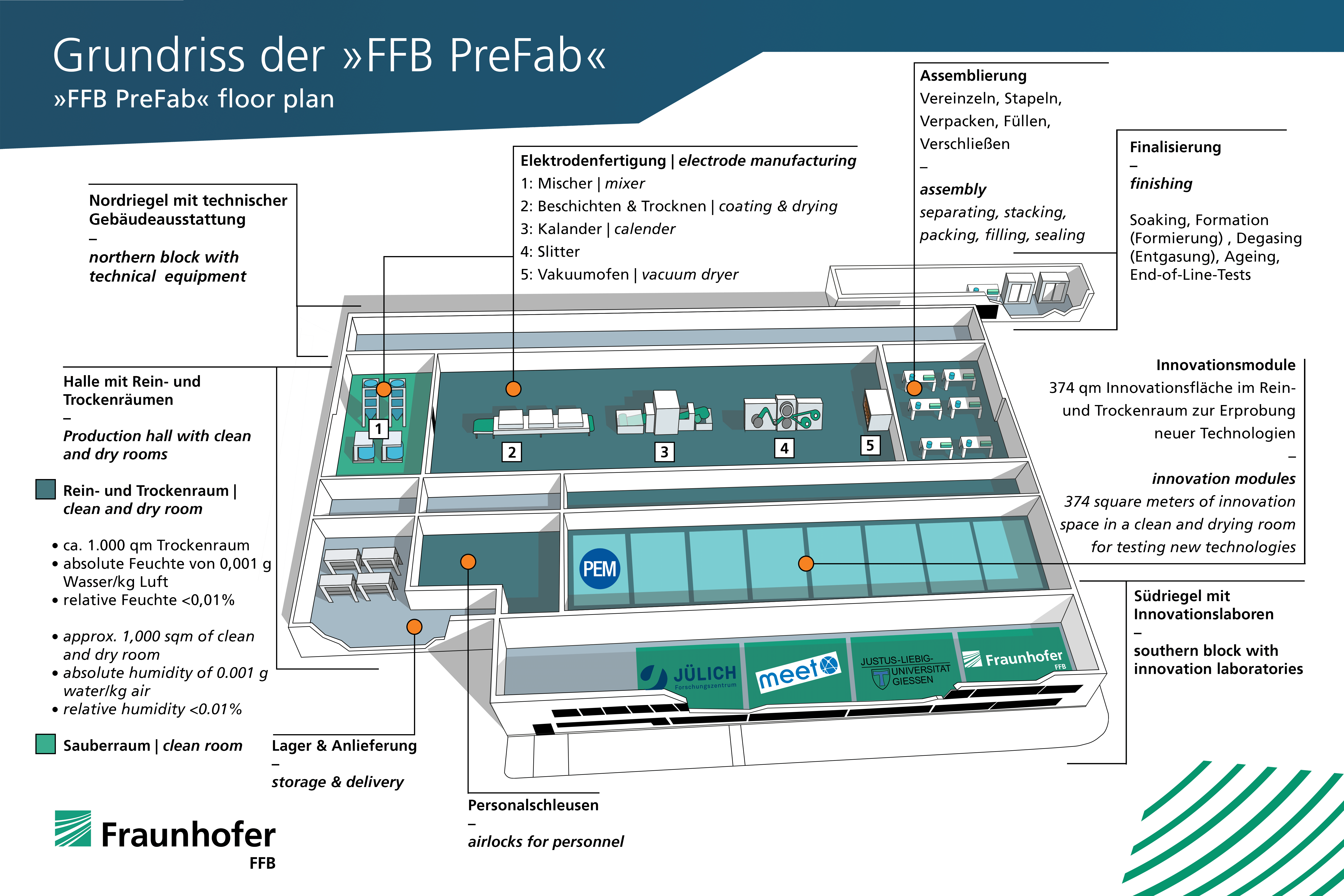

We test and evaluate innovative technologies that have proven promising at the laboratory level on an industrial scale together with our partners from research and industry. By integrating these technologies into our flexible pilot cell production in the "FFB PreFab" using innovation modules, we optimize the process of the scaling effects that occur and finally validate the process in the context of the entire battery cell production.

Companies can use our comprehensive research infrastructure to test and optimize their technologies. The findings can not only be based on the singular development topic, but the transparency of an open battery production line means that further information (e.g. quality, costs, etc.) can be made available across the board while at the same time safeguarding all property rights.