What to concider energywise when planning a Battery Cell Factory

The energy concept plays a crucial role in the planning of battery cell factories. These factories have high energy requirements for electricity, heating, and cooling, which significantly affects operational energy costs and Scope 2 emissions, ultimately impacting the overall sustainability of the factory. Even in research and development facilities like FFB Prefab, where the scale of operation is smaller than that of a Giga Factory, the focus remains on the energy concept.

The use of modern technologies for energy production enables an efficient design of the energy supply. In addition to the consumption of the process technologies, a production scenario is created that enables a forecast of the load curves over the year to be able to appropriately dimension and simulate the energy quantities and the corresponding energy producers.

In the planned energy system, four main levels have been identified:

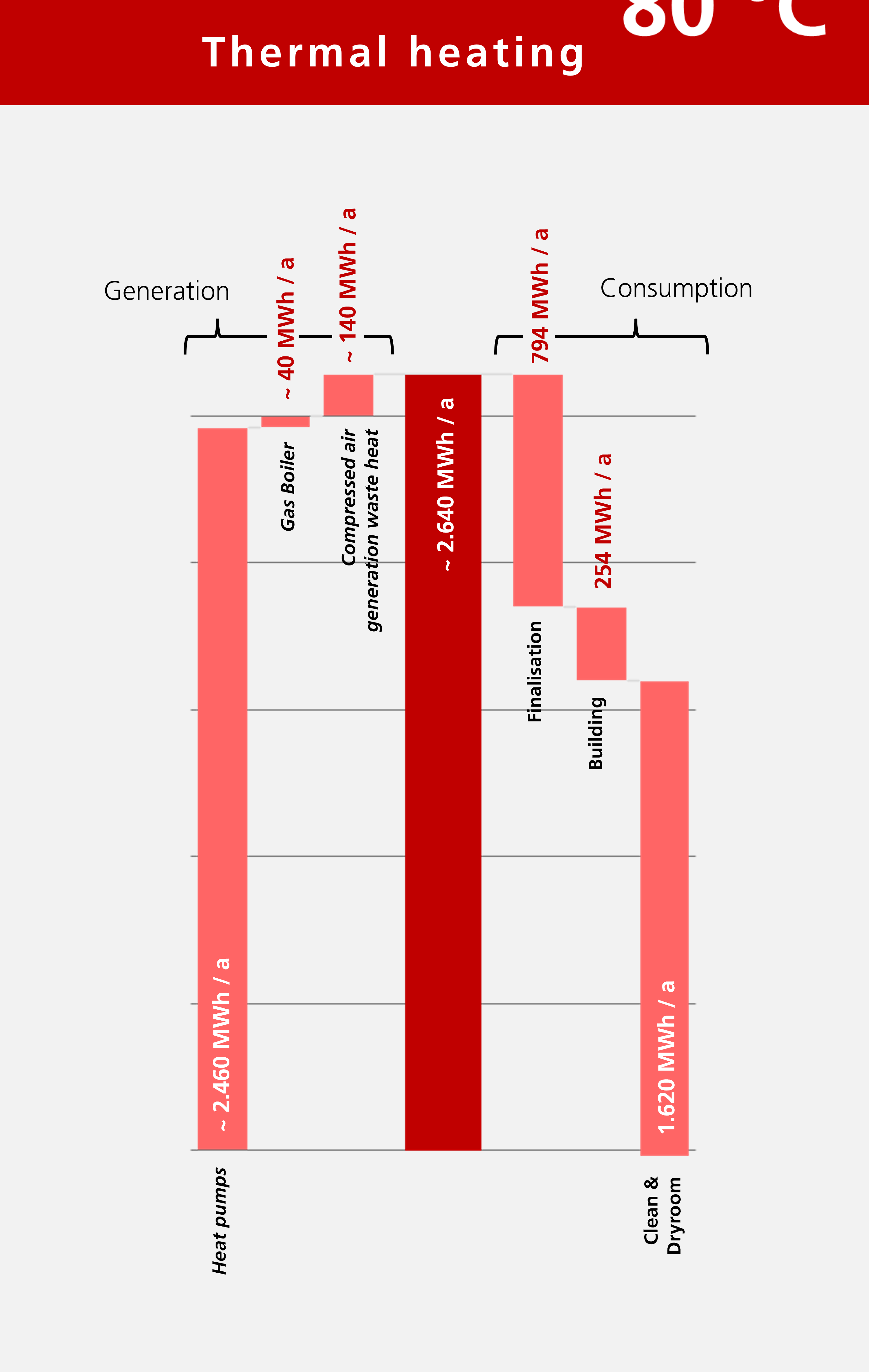

- a level for heating with a feed temperature of 80°C,

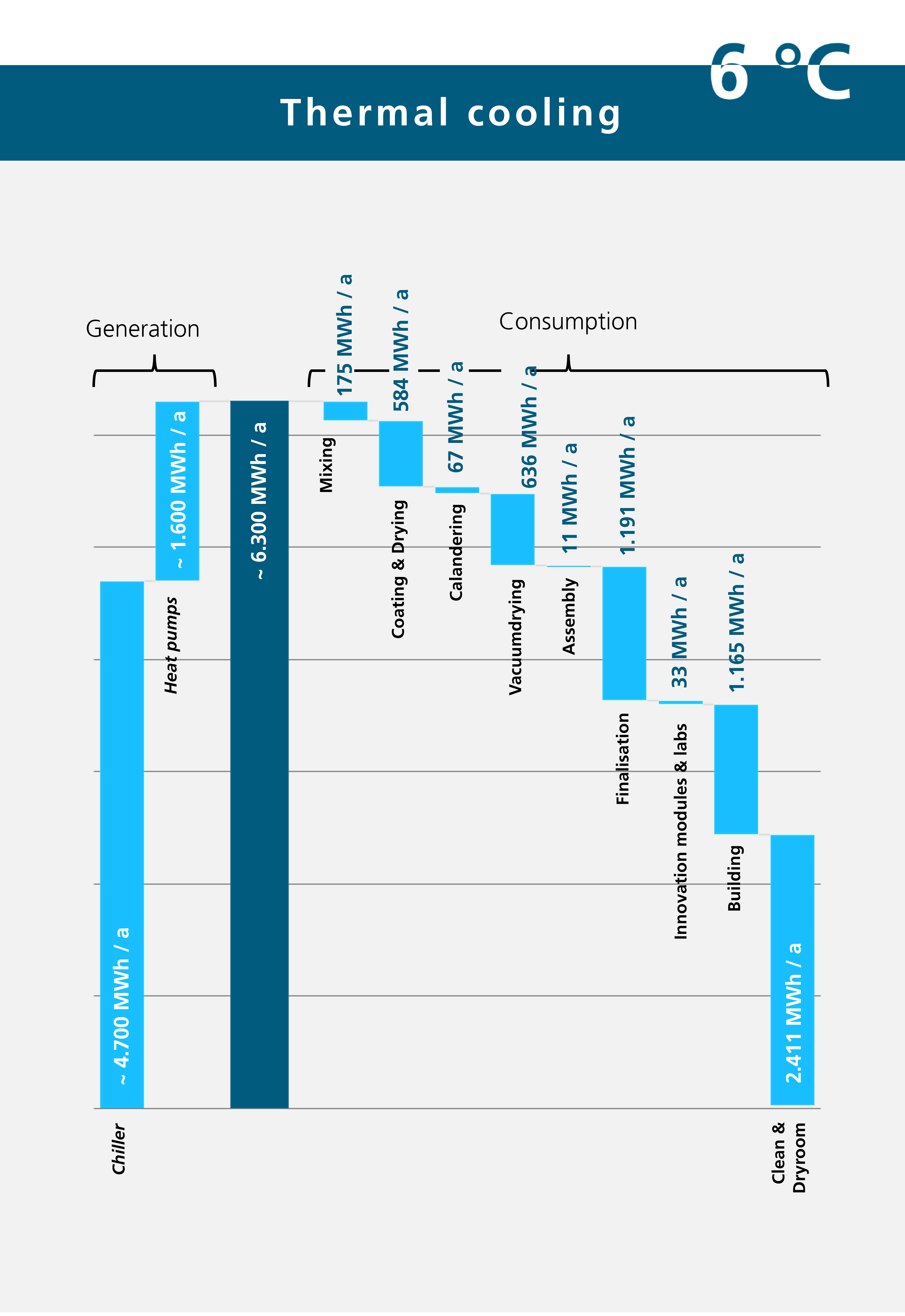

- a cooling level with a feed temperature of 6°C,

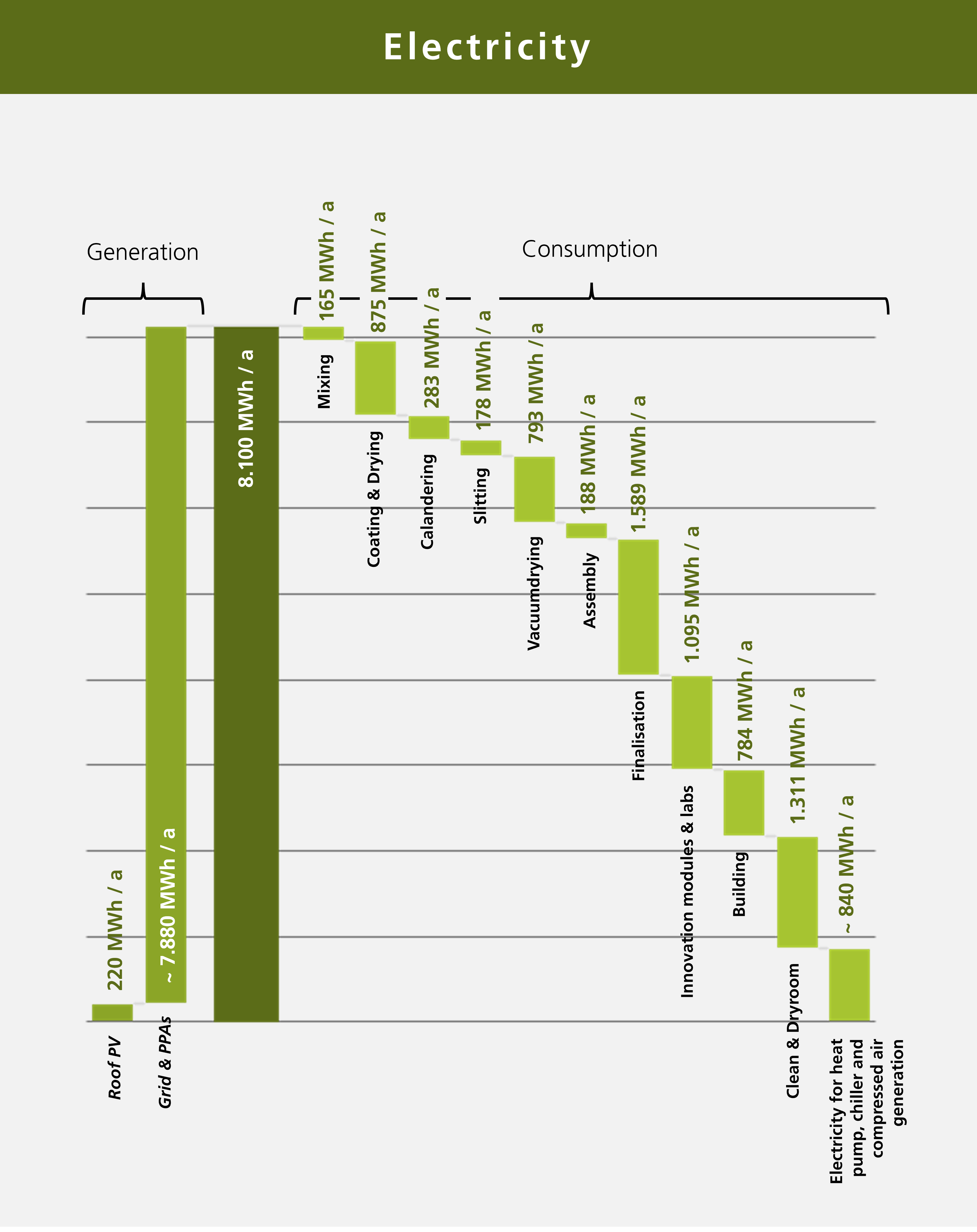

- as well as a level for supplying electricity and natural gas.

- Additionally, 0.8 GWh/a of electricity and 33 MWh/a of natural gas will be provided for heating and cooling using corresponding energy production equipment.

The first three levels will be provided with a total of 7.3 GWh/a of electricity, 2.6 GWh/a of heat, and 6.3 GWh/a of cooling.

The goal of Fraunhofer FFB is to optimize both the consumers and the energy concept itself, through energy management systems, to achieve significant energy savings. These energy savings can also be applied to gigafactories and have the potential to greatly improve the sustainability of battery cells.